Upgradeable

Can be upgraded to SCADA at any time by license

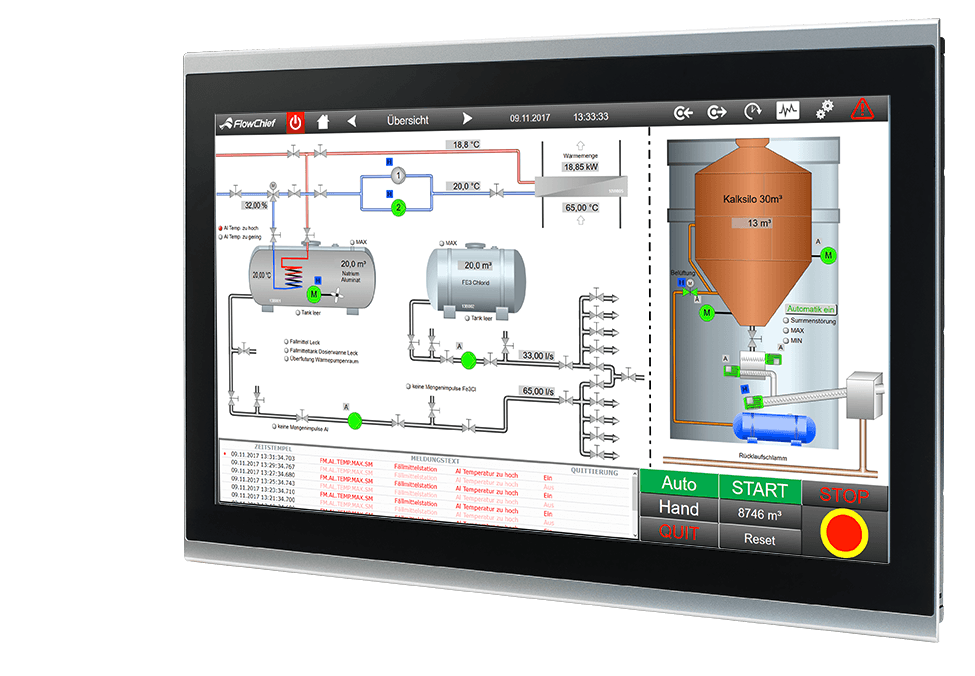

FlowChief web.HMI is the solution for operating and monitoring local machines and processes and can run independently on any PC or Panel PC.

Completely web-enabled and infinitely scalable – the FlowChief HMI visualization is a complete SCADA system without analog value archiving for direct on-site use for monitoring and operating process plants and machines.

FlowChief web.HMI can run independently on any PC or Panel PC, even without a higher-level control system . If such a system is used, operation of the HMI version is maintained even if the central unit fails. In combination with a higher-level FlowChief SCADA system, the great cost advantage is that project planning only has to be carried out once. Each configuration, process screen creation and variable system is taken over 1:1 and requires no further post-processing.

Upgradeable

Can be upgraded to SCADA at any time by license

Efficiency Increase

Create images and data points once and use them twice

100 % web-based

Operation also possible via tablet on site

VISUALIZATIONThe web browser serves as a workstation – it is available on every operating system and device type. No matter if Windows or Android, server or smartphone. |

|

MESSAGE ARCHIVEFault and operating messages are displayed chronologically and to the millisecond, with internal, external, or collective acknowledgements. Can also be integrated into visualisation images. |

|

ONLINE-WRITERDynamic online trending for the visualization of process values |

|

INTERNATIONALIZATIONEach user can be assigned his language. The administration is done with MS Excel. |

|

CONNECTIVITYSiemens S7 controllers can be directly connected via the OPC driver. Additional PLCs must be connected with a separate OPC server. |

Powerful engineering tool for creating and dynamizing process images. Working with the FlowChief imager can be done locally or remotely as TCP/IP client. Versatile formatting options: Alignment tool and the supplied extensive and cross-industry vector graphics and object libraries make it easy to create images and form the basis for great process images.

With 100% web technology, we do not limit ourselves to visualization. Pure Web at FlowChief means continuous working with the web browser in all configuration and user front ends.

Large quantities of process variables can be configured easily, quickly and very flexibly in FlowChief via Microsoft Excel™ . Programming knowledge is not necessary. The configuration can be done offline or online while the system is running. Changes are immediately available without system downtime.

The web-based assistant automatically takes the data model from the data source and eliminates error-prone and cumbersome handling of large data point lists. Process variables are generated fully automatically on the basis of the PLC configuration. Data sources such as OPC UA Server can also transmit further metadata (e.g. unit, measuring range, comments etc.) in addition to the symbolism. This makes it possible to project the complete data model decentralized in the PLC.

We are looking forward to your inquiries and comments

Even in industry, HMI software is often incorrectly evaluated and simply underestimated. The origin lies in the general validity of the term: Human Machine Interface essentially describes the user interface between man and computer, machine or plant. This is why the term “human-machine interface” is used. In principle, your mouse and keyboard are HMIs. HMI is a central topic in the engineering sciences, also on the way to an economically usable Internet of Things and Industry 4.0. More and more complex systems and plants are to be visualized more and more simply and controlled more intuitively. The reduction to the most necessary control elements with maximum manageability is a conflict on which we continue to work with the web.HMI day-to-day.