Visualization

Pure web technology. Powerful and platform independent

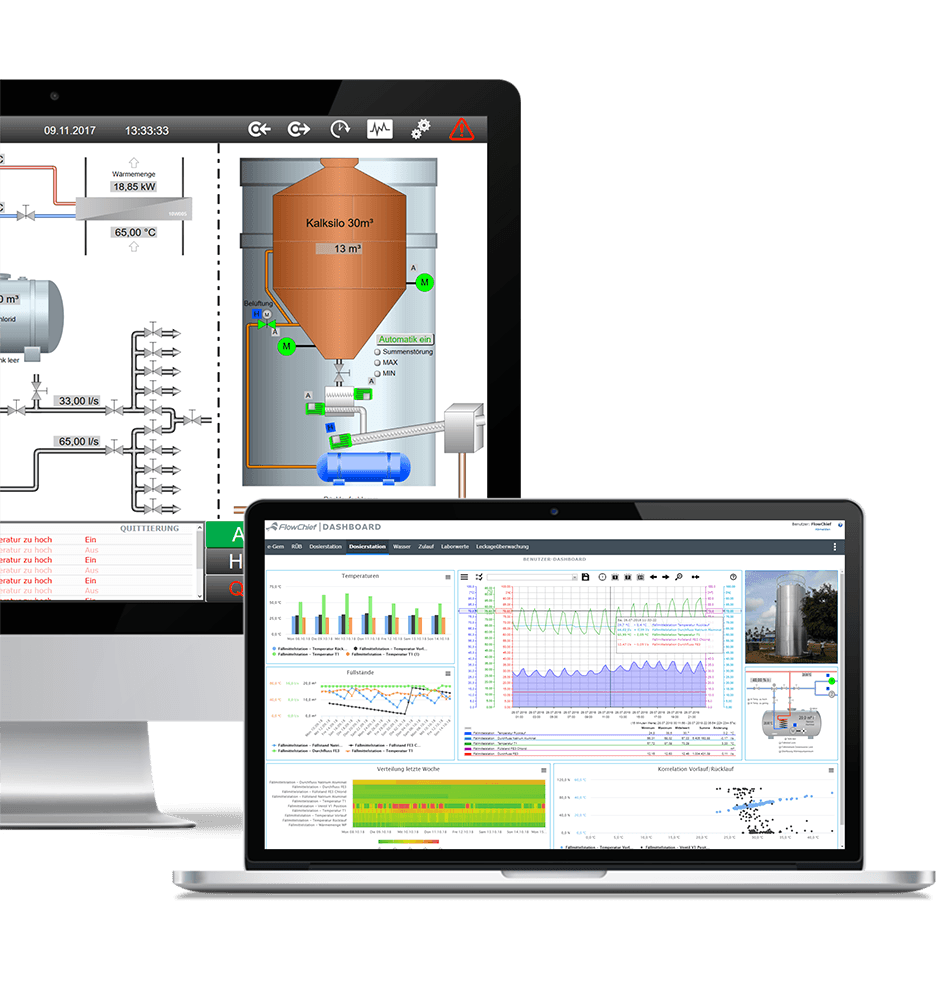

The FlowChief software platform supports many industrial and manufacturing processes. FlowChief is flexible, scalable and open for all common communication standards. From simple process operation to Industrial IoT concepts, FlowChief can be the key component for your Industry 4.0 project.

FlowChief monitors and controls machines and plants. Visualization is the most important interface for the user. Further essential functionalities are production data acquisition, analysis via trend or report functions and alerting in case of failure.

FlowChief is extremely powerful in the collection and aggregation of large amounts of data. The data can also be pre-processed (e.g. Delta Event). Integrated front-end functions such as interactive trending, dashboard, visualization or reporting provide complete transparency for the user when analyzing archive data. The access rights can be assigned finely granulated via the integrated rights and roles concept.

e-Gem integrates operational energy management into the central process control system: Consumption values are classified according to media, organizational units, meters and cost centers. The illustration of complex hierarchical structures enables accounting and creates transparency the entire usage. Flexible dashboards help to provide information in the company for energy managers, technicians, controllers or CEOs.

Visualization, alerting, historian, energy management and more

Visualization

Pure web technology. Powerful and platform independent

Dashboard

Flexible, tile based cockpit application. Use of charts, elements for visualization, message lists etc.

Archiving & Aggregation

Efficient and secure archiving including data compression

Trending

Interactive on-/offline graph-functionality; various modes: archive, archive time comparison, frequency, XY-scatter diagram

Reporting

User friendly report engine including designer

Alerting & Escalation

Intelligent alerting platform – targeted alerts via voice, text message, e-mail or app

Recipe manager & scheduler

Integrated recipe management for the simple administration of production and processes

Maintenance management

Plant and maintenance management with direct process connection and ticket system

Energy management

Integrated solution for energy management, ISO 50001 certified

HTML5 web technology is changing the world of SCADA and process control systems. Gone are the days of high-maintenance workplace installations with limited ease of use and ongoing incompatibilities between products or operating systems.

FlowChief is completely designed in pure web technology and, from the very beginning, developed to be applied in the web browser. No matter if control desk, office workstation, mobile notebook, tablet or smartphone, you connect your application – without further installation – to the intranet; via a private cloud or securely via the internet. Your FlowChief system is accessible from anywhere in the world and is not limited to pure visualization. For us, 100 per cent web means full functionality in visualization, charts, protocols, alarm management or maintenance management.

Location-independent

On-site or via word wide web

Secure and simple integration

Of the system infrastructure (firewalls, DMZ, proxies etc.)

High definition

Lossless zoom with perfect performance through W3C standardized SVG

No client installations

No more plugins or browser extensions necessary

Plattform and device independency

Web browsers are available everywhere

Future-proof and safe investment

Profit from the fast development of web technologies

Your powerful engineering tool for creating process images and animations. The FlowChief imager can be used as a local application or detached as TCP/IP-client. Multiple formatting possibilities, such as alignment tools and included libraries for vector images and objects for various industry sectors, enable a simple creation of great process images.

Using 100 % web technology we do not limit ourselves to visualization. At FlowChief pure web means consistent

operation of the web browser in all configuration and user front-ends:

FlowChief can handle huge amounts of process variables much easier and more convenient by inserting the configuration in a Microsoft Excel™ spreadsheet. Programming skills are not necessary. Configuration can be done offline or online while the system is running. Changes are immediately available, without any downtime:

The web-based assistant automatically transfers the data-model from its source and therefore prevents complicated handling of large data-point lists. Process variables are generated fully automatic on the base of the PLC configuration. Data resources like OPC UA servers cannot only transfer symbols but also metadata (e.g. units, measurement range,

comments, etc.). Thereby it is possible to plan all data, decentralised, in the controller.

For the Koller Group, a supplier to the automotive industry, SPANGLER Automation has combined the advantages of machine and building control technology in FlowChief. The data are further evaluated in e-Gem. With this, specifications can be adhered to and e.g. the maintenance requirement can be recognized.

Sewage sludge is dried in order to minimise its quantity and thus transport and disposal costs. SPANGLER has automated a Huber SE belt dryer with control technology from FlowChief. The dry material can be stored and opens up new disposal and recycling paths.

SPANGLER and the dumpling specialist Burgis relied on FlowChief for the construction of the new production facility. All processes from delivery and storage, sorting and washing to the production lines are recorded and documented. This is because strict regulations on traceability apply to food.

Infraserv Höchst uses FlowChief as data hub and historian server. FlowChief is predestined for this job: 1. Flexible and open communication with different data sources. 2. the web frontend offers perfect possibilities to make collected data available to a large number of users in the form of graphs, dashboards or reports.

The SCHOTT technology group, which specializes in glass production, has been using FlowChief’s ISO 50001-certified energy data management system e-Gem since 2011. e-Gem acts as a data hub within the company. Energy planning, peak load optimization, billing and technical services continuously access the data and use it for their individual…

The decisive factor for a FlowChief process control system was the uniquely integrated overall concept. Apart from the FlowChief process control system, there is no product on the market that offers an innovative and plugin-free web visualization with powerful historization, reporting and alarm platform in one application.

We are looking forward to your inquiries and comments.

In 2012, we decided to modernize the aging Repas AEG process control system. After an extensive market analysis, the choice fell on FlowChief. The decisive point was above all the uniquely consistent overall concept of the application – so there is no comparable product on the market, which offers a plugin-free web visualization with historian server and alarm platform combined. Meanwhile, we also trust FlowChief with our in-house energy data management.