Location-independent

on-site or via world wide web

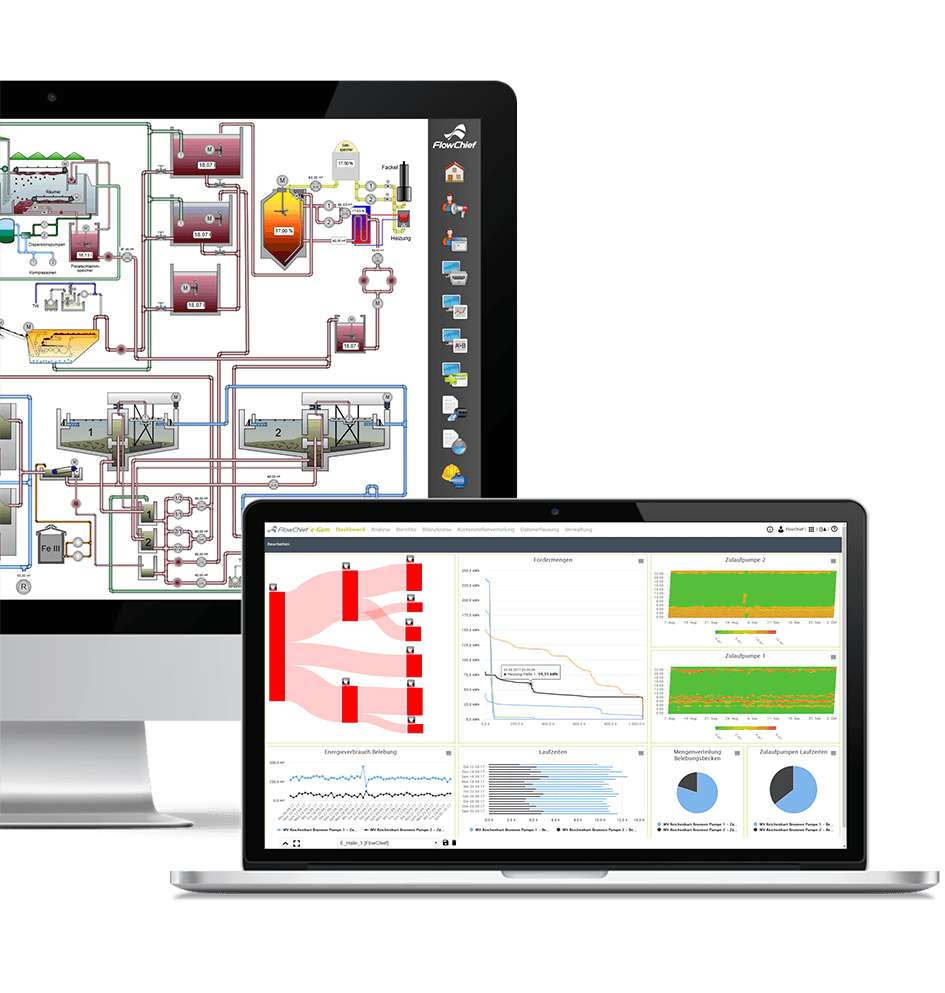

Most advanced process control technology of FlowChief serves as central intelligence of the entire infrastructure and is the window for the operator into his plants.

In the central waste water treatment plant, the waste water is treated in various process engineering steps and returned to the water cycle. Ensuring error-free operation and complete recording of all process data are mandatory.

Waste water networks ensure the disposal of waste water to the sewage treatment plant. State-of-the-art measurement and control technology in pump stations, lifting structures, level measurement stations or vacuum drainage systems are securely connected to the central control system via remote control technology.

Reservoirs and flood plains store large quantities of water and reduce the peak values of flood waves. The recording of water levels serves to inform the population in the event of a crisis and is also important for the analysis of flood events.

Rain spill basins protect the wastewater treatment plant from overloading in the event of heavy rainfall. The basins serve as storage tanks and throttle the outflow in the direction of the wastewater treatment plant. The data collected by measurement and logging are an important basis for settlement planning and research on water discharge during heavy rainfall events. A transmission to public authorities is obligatory in many places.

HTML5 web technology is changing the world of control technology. Gone are the days of high-maintenance workplace installations with limited ease of use and ongoing incompatibilities between products or operating systems.

FlowChief is completely designed in pure web technology and, from the very beginning, developed to be applied in the web browser. No matter if control desk, office workstation, mobile notebook, tablet or smartphone, you connect without further installation with your application on the intranet, via the private cloud or securely via the internet. Your FlowChief system is accessible from anywhere in the world and is not limited to pure visualization. For us, 100 per cent web means full functionality in visualization, charts, protocols, alarm or maintenance management.

Location-independent

on-site or via world wide web

Secure and simple integration

into the system infrastructure (firewalls, DMZ, proxies etc.)

High definition

Lossless zoom with perfect performance through W3C standardized SVG

No client installation

No more plugins or browser extensions necessary!

Platform and device independent

Web browsers are available everywhere!

Future-proof and safe investment

Profit from the fast development of web technologies!

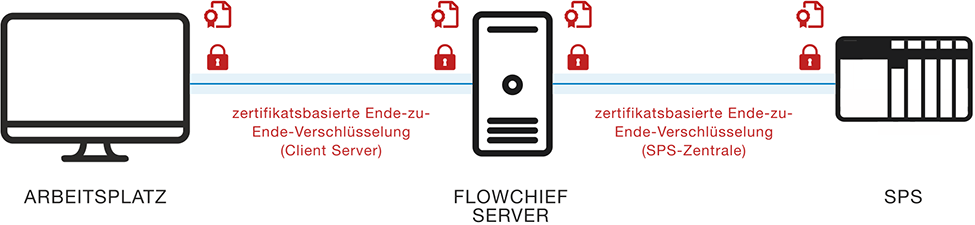

FlowChief is developed for operation in critical infrastructures. We rely on 20 years of experience in the development of secure web applications and remote control technology.

FlowChief systems can be upgraded at any time to a highly available and fail-safe redundancy solution. This maximization of availability prevents blind flights or data gaps, which can always occur due to network, communication or server hardware failures. FlowChief redundancy is based on Microsoft's failover clustering. All system functions such as browser visualization, communication, archiving, curves, reports or alarm management are still available even in case of failure.

The FlowChief operating diary for sewage treatment plants is a software-based protocol to comply with the operating obligations according to the self-control regulation of the federal states. The FlowChief operating diary is a program from the practice for the practice, clearly and simply operable.

The integrated event recording of FlowChief is manufacturer-independent for the measurement technology. Buildings can also be monitored without power supply. The acquisition of data in Ex-protected areas is also possible. The acquisition and the creation of protocols run fully automatically within FlowChief. If no own central control technology is available, the buildings can also be connected to a FlowChief portal service for a monthly fee.

A large variety of Data loggers are offered on the market, but it is essential to have a closer look at these.

A prime example of purposeful flood protection is the Sulm water board. All basins were connected to FlowChief via path redundancy in order to secure the application in case of catastrophe. A level overview connected to the association’s website enables the population to call up the current water levels.

Sewage sludge is dried in order to minimise its quantity and thus transport and disposal costs. SPANGLER has automated a Huber SE belt dryer with control technology from FlowChief. The dry material can be stored and opens up new disposal and recycling paths.

The municipality of Mühlhausen operates a municipal waterworks, one main and two secondary sewage treatment plants. SPANGLER combined the systems with FlowChief technology into one central control system. This allows the operators to switch to the different plant components from any location without an employee having to be on site.

With a capacity of 85,000 inhabitants, Kitzingen’s sewage treatment is by far the largest in the district. In the catchment area there are 22 rainwater overflow basins, 10 pumping and 6 measuring stations. The employees themselves created more than 100 process pictures for the visualization with the FlowChief Imager.

We are looking forward to your inquiries and comments.

You are unique as a customer and so is your project. We know this from 2,000 projects that have been implemented by our system integrators and ourselves.

Our services include:

Regardless of whether the region is sparsely populated, rural or urban – for the treatment of municipal and industrial wastewater and to cope with heavy rainfall, a coordinated infrastructure of sewer networks, pumping stations, rainwater overflow basins and sewage treatment plants is required. All of these systems operate mostly fully automatized. Most advanced process control technology from FlowChief serves as the central intelligence of the entire infrastructure and is the window for the operator into his plants.

Since 2006, we have relied on FlowChief for the central process control system. The big advantage of the FlowChief system structure, is the integration of many important functions of our control technology into one software. From visualization and archiving to reporting and maintenance management – up to 15 employees from the control center, specialist workshops and operations management work with the system on a daily basis. Prerequisite for this is the consistent execution in HTML5 web technology. The system is designed as a hot standby redundancy solution – the reliability is also ensured in exceptional situations, such as hardware defects.