HTML5

100 % pure web technology

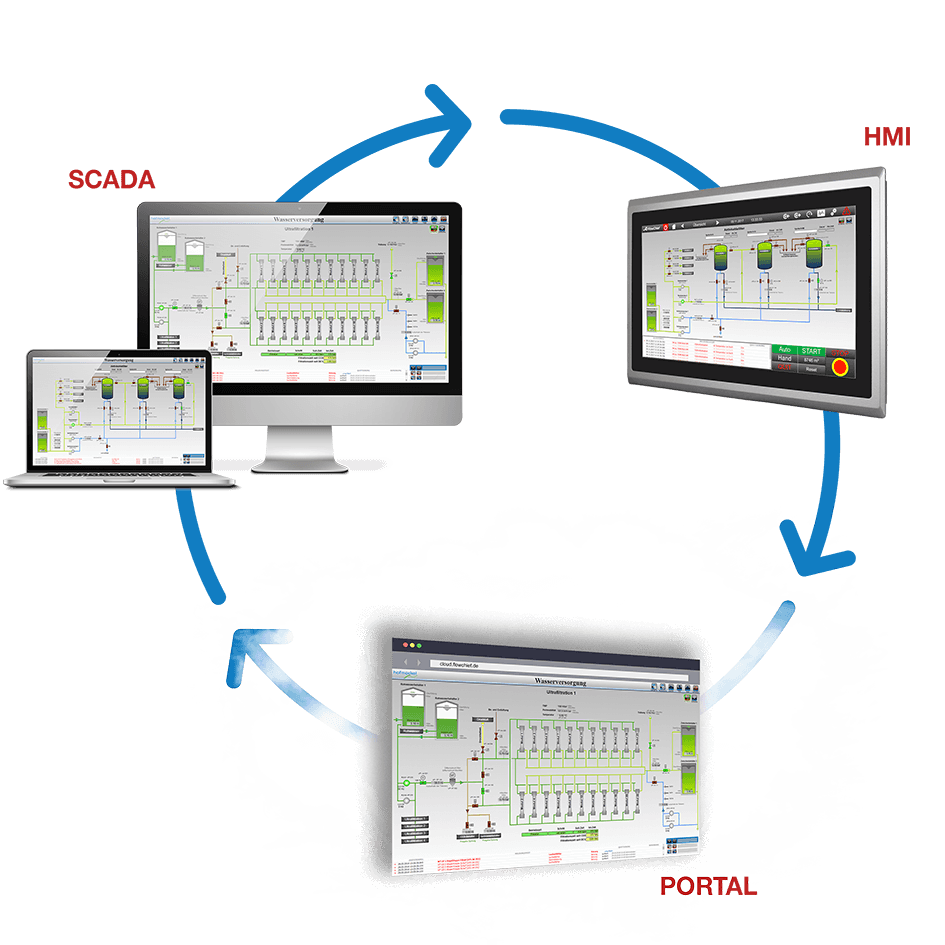

From the very beginning FlowChief has relied on web technology. This is an elementary component of the FlowChief DNA. With the fully integrated OPC UA functionality we not only talk about the often cited vertical integration, we are also offering solutions. The use of controllable standards additionally guarantees the security of your data.

Every plant is different, every customer has different focuses – FlowChief adapts to your individual needs. A modular software architecture and licensing make it possible: Scalable in functional scope and system size, updateable at any time for well over ten years.

low maintenance

no interfaces between individual products

cost savings

during integration and especially in operation

easy product updates

no compatibility problems after updates

FlowChief’s central component is a powerful and reliable visualization. High-performance updating of all data and very fast image changes, both for single-user solutions and for access via the network. In addition to message lists, trends and charts, external sources such as Google Maps or HTML webcam streams can also be embedded in the individually designed interfaces. Without pixelation, a wide variety of detailed information can be dynamically faded in and out using the zoom function. Secure access is guaranteed by password policies with optional 2-factor authentication and authenticity certificate-based data transfer.

Always have the most important data of your business in sight, with the dashboard – compact, simple and organized. Widget elements such as speedo, bar graph, aggregates or diagrams can be put together easily and intuitively. In addition, visualization elements, text messages, Google Maps or webcams can be easily integrated. The responsive web design makes the dashboard suitable for all display sizes – PC monitor, tablet, smartphone. In addition to simply duplicating existing dashboards and creating new ones, it is also possible to share them with colleagues through with only one touch of a button.

The powerful historian functionality allows you to archive digital, analogue and meter data across time zones and to the millisecond. Archiving (delta event, cyclical, historical) and compression (15-minute, hourly, daily, monthly and annual values) can be individually parameterized for each variable. The consistent database model offers full transparency for visualization, trends, reports and export as well as full traceability of manually corrected process values. The security of your data is guaranteed by redundancy, backup & recovery and outsourcing functionalities.

Several plotter modes enable you to perform a variety of demand-oriented evaluations of all analog, digital or counter values. In addition to the obligatory online recorder, an archive and time comparison mode as well as a frequency analysis and an XY scatter diagram are also available. Flexible control functions such as mouse pointer, envelopes, limit values, min/max values, etc. together with modern multi-touch gestures round off the intuitive user experience. The various graphic display variants such as color, time domain, resolution, diagram type (line, bar, area, etc.) can be easily selected with a mouse click. Plotter combinations can not only be saved for private use, but can also be flexibly shared between different users.

Several report modules open up unlimited possibilities for creating reports. Fixed defined reports can be parameterized and automatically generated at regular time intervals as well as dynamic dashboards. With the integrated designer, tables and diagrams such as cakes, columns or bars can also be integrated. The reports can be created as WebReports in HTML, so that they are available platform-neutral with every web browser and on all devices. A Microsoft Excel-based reporting system is also available for complex company solutions.

The self-sufficient energy dashboard helps you to recognize energy saving potentials and to operate your plant more sustainably. All consumption data of your plant is recorded independently of the media. Performance indicators (KPI) are created to evaluate efficiency. The historicization of organization, metering points and tariffs is possible independent of the process control system.

The intelligent alarm platform ensures maximum system availability through targeted alarming in the event of a fault. Through the long-term archiving of all operating and fault messages, historical events can be completely traced and evaluated with the aid of frequency analysis. Based on priorities and alerting parameters, the system decides on the urgency and alerts user-specifically via voice call (also VoIP), SMS, push notification or e-mail. The software also enables complete standby and shift planning, including calendar function, dropping, parallel alarming and escalation of alerting channels.

With the direct process connection for tracking operating hours and important measured values, the clearly arranged operation management tool supports the administration of machines and plants including their accompanying documentation. Repairs and preventive measures can be logged with printed or electronic routing slips. The permanent storage of all events enables the generation of clear machine life cycles.

FlowChief has an integrated recipe management and task planning for the simple administration of complex control parameters for the discrete manufacturing or process industry. Plant parameters can be easily adjusted to production and activated batch-related. In the process industry, complex processes can be controlled with coordinated target value rates. Switching commands and setpoints can be executed time-dependently and archived and reported as operating messages.

Web App for unlimited access to your machines and processes!

FlowChief scadaApp enables you an easy and reliable access with mobile operating devices to your FlowChief SCADA or web.HMI.

FlowChief systems can be upgraded at any time to a highly available and fail-safe redundancy solution. This maximization of availability prevents blind flights or data gaps, which can always occur due to network, communication or server hardware failures. FlowChief redundancy is based on Microsoft's failover clustering. All system functions such as browser visualization, communication, archiving, trends, reports or alarm management are still available even in case of failure.

FlowChief records and archives events to the millisecond. The data is recorded via OPC, OPC UA Data Access or Alarm & Events. In addition to the time stamp, the source, the priority (severity), the description and the status are also recorded. The FlowChief reporting archive is the central surface for the administration and analysis of disturbances. Depending on the message, the user can acknowledge, enter a comment or initialize a maintenance task. In addition to the chronological evaluation of all messages, messages within time ranges can also be analyzed for frequency.

FlowChief has a role-based user administration with an extensive rights concept. A multitude of parameters can be used user-specifically: Language switching via country code, alarm parameters or security settings such as two-factor authentication. With FlowChief it is easy to interface with the existing user management using the existing Windows Active Directory. Visualization, trends, dashboard and much more can be configured individually for each user.

The FlowChief rights management regulates the access (reading, writing, configuring, executing) to the process and the different FlowChief functions. The parameterization can be done by the user or clearly via user groups. FlowChief structures plants hierarchically – it is possible to configure rights for specific plant sections, without restriction. This is the prerequisite for the continuous multi-client capability in FlowChief.

FlowChief is developed from scratch for multilingual use. Depending on the language, each user receives a specific country code. The translations are flexibly maintained via a supplied Excel folder. This can easily be linked to existing translation databases. Language files are generated automatically at the push of a button. The complete system is translated, from the configuration to the process images to the system UI. The system user interface is available in German and English as default and can easily be extended to the language of the respective user.

The FlowChief Audit records user actions during system operation and configuration changes during engineering. If required, user actions can be easily tracked and analyzed via a flexible interface (Audit Trail). Safety-related processes such as failed login attempts are also reliably recorded in the archiv. If required, audit entries can be cyclically transmitted to third-party systems via a reporting service. The following activities are recorded:

The imager is a powerful engineering tool for creating and dynamizing process images. Working with the FlowChief imager can be done locally or remotely as a TCP/IP client. Versatile formatting options: Alignment tools and a large variety of cross-industry vector graphics and object libraries are the foundation for great process images.

With 100% web technology, we do not limit ourselves to visualization. Pure Web at FlowChief means continuous working with the web browser in all configuration and user front ends.

Large quantities of process variables can be configured easily, quickly and very flexibly in FlowChief via Microsoft Excel™ . Programming knowledge is not necessary. The configuration can be done offline or online while the system is running. Changes are immediately available without system downtime.

The web-based assistant for automatic transfer of the data model from the data source makes error-prone and cumbersome handling of large data point lists superfluous. Process variables are generated fully automatically on the basis of the PLC configuration. Data sources such as OPC UA server can also transmit further metadata (e.g. unit, measuring range, comment etc.) in addition to the symbolism. This makes it possible to project the complete data model decentrally in the PLC.

Since 2011, the power plant of the district of Schwyz has been monitoring the power grid infrastructure on the generator and customer side with process control technology from FlowChief. FlowChief visualizes, monitors and controls network components such as circuit breakers, protection devices or transformer monitoring.

The municipality of Marktoberdorf has been operating its own district heating network since 2009. During the expansion in 2012, the decision was made to monitor the operation of the plant with a central process control system. FlowChief is also used there for visualisation, alarming, historisation maintenance and heat management.

Sewage sludge is dried in order to minimise its quantity and thus transport and disposal costs. SPANGLER has automated a Huber SE belt dryer with control technology from FlowChief. The dry material can be stored and opens up new disposal and recycling paths.

SPANGLER and the dumpling specialist Burgis relied on FlowChief for the construction of the new production facility. All processes from delivery and storage, sorting and washing to the production lines are recorded and documented. This is because strict regulations on traceability apply to food.

The SCHOTT technology group, which specializes in glass production, has been using FlowChief’s ISO 50001-certified energy data management system e-Gem since 2011. e-Gem acts as a data hub within the company. Energy planning, peak load optimization, billing and technical services continuously access the data and use it for their individual…

The decisive factor for a FlowChief process control system was the uniquely integrated overall concept. Apart from the FlowChief process control system, there is no product on the market that offers an innovative and plugin-free web visualization with powerful historization, reporting and alarm platform in one application.

We are looking forward to your inquiries and comments

Almost every modern large-scale plant, but also plants and systems in many small and medium-sized companies, are controlled and monitored in one way or another with a SCADA system. The long form of the name – Supervisory Control and Data Acquisition – describes precisely what the system is intended for, namely to control and collect data. In contrast to pure visualization, data processing in operational diaries and reports is an elementary component of a SCADA system.

SCADA solutions like FlowChief are therefore not only to be found in widespread water and wastewater systems but also operate at energy suppliers, photovoltaic plants, facility management, in medium-sized biogas plants or in large building complexes.

At Zeppelin Power System we offer our customers tailor-made all-round carefree packages with our solutions for combined heat and power plants and marine installations. In FlowChief we found a partner with modern software and the necessary flexibility. That’s how we offer FlowChief based software solutions to customers – from simple machine operation to marine fleet management.