360° energy data management at SCHOTT AG

Presentation of “Transparency from the meter to the cost center” on ENERGY 4.0 Stage at Hannover Messe 2023 (in German)

watch on YouTubeSCHOTT is one of the world’s leading manufacturers of specialty glass, glass-ceramics and other high-tech materials. The technology group employs round about 17,200 people at over 30 locations worldwide. The overall corporate goal of Zero Carbon stipulates a climate-neutral production by 2030 (Scope 1 & 2 GHG Protocol). The intensive process of glass melting combined with the corporate goal, take energy consumption and the data of individual energy sources to a higher importance.

FlowChief has been the central hub for energy data within the company since 2011 and is therefore the central hub for around 35,000 data points and 250 users.

The level of energy management at SCHOTT is now very high. With FlowChief, we have a partner that offers the necessary flexibility and quality.

Lothar Kretschmer

Head of Energy Economics / Energy Management, SCHOTT AG

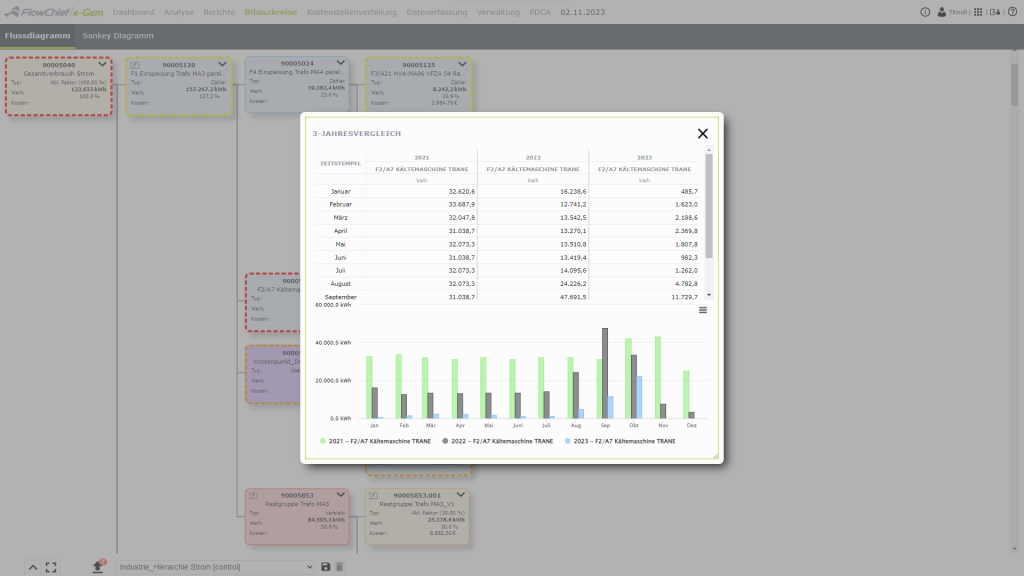

The scalable platform functions as a global SCHOTT energy data management system including billing. The energy control system at the site in Mainz is also part of the solution. FlowChief manages the balancing act between the different requirements of these areas. Reliable archive data is essential for energy management. The focus in energy management lies on monitoring and controlling the systems (electricity and natural gas supply, compressed air and cooling generation, water technology, etc.) in real time.

Aerial view of the SCHOTT site in Mainz (Source: SCHOTT)

Aerial view of the SCHOTT site in Mainz (Source: SCHOTT)

A particular challenge is the heterogeneous, cross-location data collection. As a manufacturer-independent system, FlowChief can be flexibly integrated into the existing infrastructure. The heart of the system is the highly available, redundant server at the main site in Mainz. The energy data from the global sites converge here in various ways.

All data is available both in real time for process visualization and alerting and as archive data for energy data management. In addition, third-party systems within and outside SCHOTT AG are supplied with data via standard interfaces such as OPC-UA or an automated MSCONS export. Energy supply companies also receive load profile information via FTP push.

Presentation of “Transparency from the meter to the cost center” on ENERGY 4.0 Stage at Hannover Messe 2023 (in German)

watch on YouTubeBased on the detailed database, the e-Gem energy management module provides the software tools required for energy management in accordance with ISO 50001.

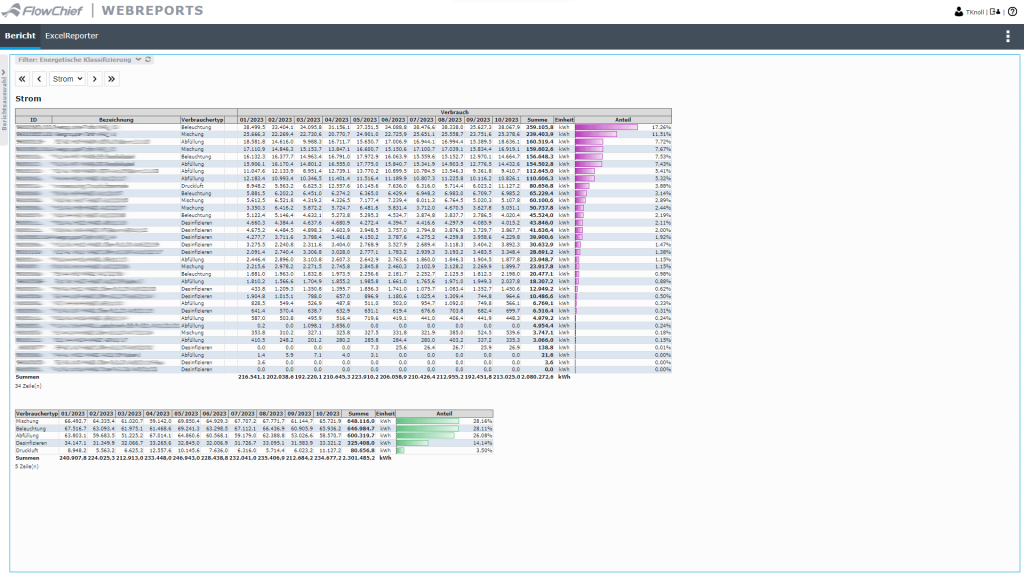

Standard report on energy classification (consumer types not original)

Standard report on energy classification (consumer types not original)

Rising energy costs are increasingly focusing attention on the internal distribution of energy costs according to who is responsible. The process is now fully reproduced in the software.

Plausibility check of the measurement concept

Plausibility check of the measurement concept

The requirements for energy data are becoming increasingly complex and fast-moving. It is already clear today that end-to-end transparency of energy consumption – from the meter to the cost center – will be crucial for the future success of the company.